additional services

How can we help?

For over 20 years our Project Managers have been working in industrial plants, Troubleshooting, Electrically disconnecting and reconnecting Equipment, Safety inspections, Safeguarding, Designing and Fabricating Control Panels, Retrofitting machines with new controls, integrating lines with robots, programming and PLC services along with an array of many other services.

Our knowledge of various types of equipment and industrial processes provides a great advantage and understanding for all phases if industry, from basic wiring to programming and production.

What we can do.

Give us a call and our Project Managers will work with you to review your needs. We welcome inputs from your Engineers, Maintenance, Safety, Production and Management teams about your issues, expectations, production requirements and budgets.

Fabrication

We can supply a turn key project for all your machine requirements. Our fabrication shop, UL listed panel shop and hand picked support suppliers will transform your machine to an updated, reliable user friendly piece of equipment, with just one call and purchase order.

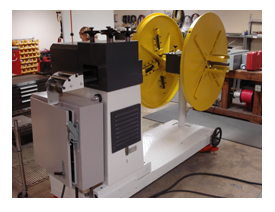

AUTOMATED TUBE FORMING

This Specialized system was designed to eliminate the manual operation of positioning tubing in die, cycling press and removing parts. This project reduce labor cost, increase production, provided a safer working environment and allowed for future automation.

specialized equipment retrofitting and process improvement service

What do you want?

Do you have a need to improve a machine or process?

Cost of a new machine along with the delivery time, transportation, rigging, installation and lead time makes justification beyond your companies requirements and Return On Investment?

Are you losing valuable production due to outdated electrical components and trying to make it day by day?

You need something better and not sure which direction you need to go or who you can trust?

If your work force has declined and you have lost or will be losing skilled personnel that keep your machines running?

Control reliability of your equipment does not meet Safety requirements?

You could install robots to increase production or improve safety, but your equipment is not reliable or accurate enough?

There are many reasons to look at retrofitting equipment and improving processes. If you are looking for an established, experienced company with Project Managers that understand industry, call us today, let us help.

What we have done.

Over the years we have updated many pieces of equipment and improved processes. The machines have ranged from Punch Press to highly specialized equipment. Here are some examples:

| PRESS CELL AND SERVO TECHNOLOGY RETROFIT | |

|

|

| Press was completely rebuilt and controls updated. Control panel and PLC were designed, built and programmed to run in a cell with press and various other pieces of equipment. System replaced gears using servo technology. Units were modified in our facility, tested and shipped to customer where Project Manager assisted with start up and production. | |

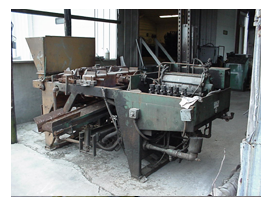

| LEVELER REFURBISH | |

| Leveler before refurbished | Leveler after mechanically refurbished and new Electrical system installed. |

|

|

| SPECIAL PRECISION FORMING MACHINE | |

| Special designed machine used to form high precision parts. Unit was transported to our facility where new controls, programming Siemens PLC and controls were installed and tested. Job completed ahead of schedule saving customer valuable production time, money and eliminated safety issues involved in hand forming parts. | |

|

|

| CONVEYOR AUTOMATION | |

| Customer was having safety issues on their conveyor line due to operator pushing 800lb. units. The refrigerators would enter the test area and operator would manually push the unit to the test cell, test and then manually push unit back on the exit Conveyor. The picture on the right shows the conveyor after modifications. The new process automatically brings unit to testing area. The operator selects (by pushing a button) which cell the unit advances to in order to be tested. Once test is completed, the operator pushes the exit button which automatically sends unit back to exit conveyor. Upgraded conveyor system, PLC and controls was installed over shutdown schedule and with no down time during start up. | |

|

|

| SAND MOLD MACHINE | |

| Machine was retrofitted with new controls and custom fabricated guarding | |

BEFORE |

AFTER |